Electrical systems are the backbone of modern buildings, powering everything from essential lighting to advanced machinery. Yet, hidden faults or failing components can quickly become costly or even dangerous if left unchecked. For property owners and facility managers searching for preventive maintenance tools, Thermographic Scan Electrical Atlanta, GA solutions have become an increasingly popular search phrase. By integrating advanced thermal imaging technology, these scans provide a non-invasive, highly accurate way to pinpoint electrical issues before they escalate. Thermographic Scan Electrical Atlanta, GA is not just a buzzword—it’s a practical approach to safeguarding your property and investments.

Why Thermographic Scanning Matters

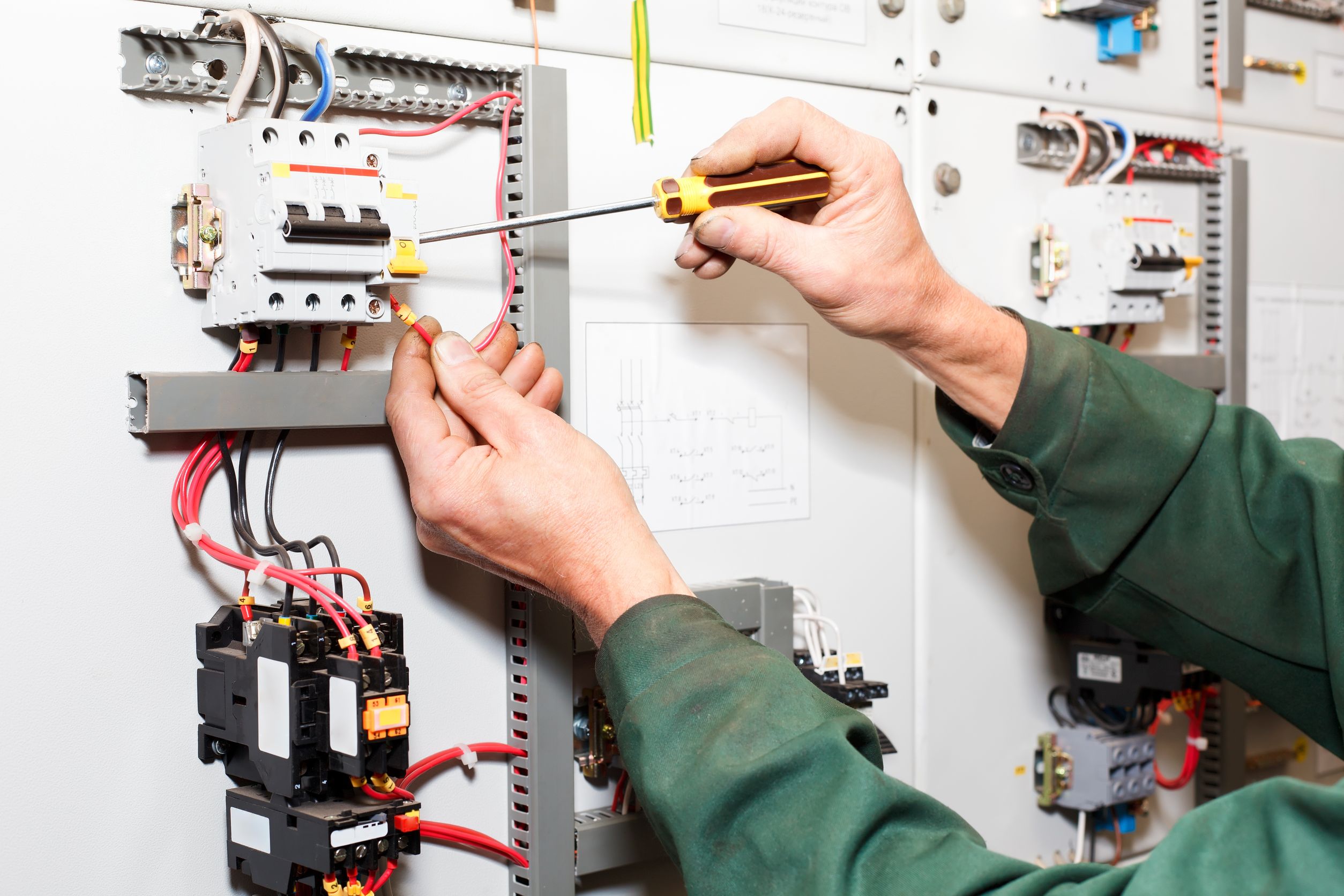

Thermographic scanning, also known as infrared scanning, is a cutting-edge diagnostic technique used to assess the health of electrical systems. Unlike traditional inspections that rely on visual cues or manual testing, thermographic scans use infrared cameras to detect heat signatures emitted by electrical components. Excess heat is often the first indicator of problems such as overloaded circuits, loose connections, or failing breakers.

The significance of early detection cannot be overstated. Electrical faults are a leading cause of fires in both residential and commercial settings. By identifying hot spots and abnormal temperature patterns, thermographic scanning allows for timely interventions that minimize the risk of equipment failure, downtime, and hazardous incidents.

Key Benefits of Thermographic Scans

- Non-Invasive Inspection: No need to dismantle equipment or disrupt operations. Scans are performed while systems are running.

- Accurate Diagnostics: Pinpoints issues invisible to the naked eye, such as internal wiring faults or overloaded components.

- Cost Savings: Prevents expensive repairs and unscheduled downtime by addressing problems before they worsen.

- Comprehensive Reporting: Detailed reports with thermal images help prioritize necessary repairs and document compliance with safety standards.

How Thermographic Scan Electrical Atlanta, GA Solutions Work

When a thermographic scan is performed, trained technicians use specialized infrared cameras to survey electrical panels, switchboards, transformers, and other critical components. The camera detects variations in surface temperature, which are displayed as color-coded images. Areas with elevated temperatures, known as hot spots, are flagged for further investigation.

Common issues detected during a thermographic scan include:

- Loose or corroded connections

- Overloaded circuits

- Imbalanced electrical loads

- Deteriorating insulation

- Faulty breakers or fuses

These scans are particularly valuable in settings with complex electrical systems, such as manufacturing facilities, office buildings, and data centers. Regular thermographic inspections can be scheduled as part of a proactive maintenance program, reducing the likelihood of unexpected outages and extending the lifespan of critical equipment.

Integrating Thermographic Scans into Your Maintenance Strategy

For property managers and business owners, incorporating thermographic scans into routine maintenance is a wise investment. Not only do these scans enhance safety, but they also support regulatory compliance and insurance requirements. With detailed documentation and actionable insights, decision-makers can prioritize repairs, plan upgrades, and allocate maintenance budgets more effectively.

In summary, thermographic scanning provides a reliable, non-invasive method for detecting electrical issues before they become critical. By leveraging Thermographic Scan Electrical Atlanta, GA solutions, property owners can ensure safer, more efficient operations and avoid costly disruptions.

Take the first step toward a safer, more reliable electrical system—schedule a thermographic scan today and protect your property from hidden electrical hazards.